Who we are?

We are an innovative sustainable environmental solutions company managed by a group of professionals.

We developed our own pyrolysis technology and are technology driven.

We are based in Hong Kong.

Our Intellectual Properties

Our Aim

We intend to make use of our pyrolysis technology and processing techniques to customize a waste plastic recycling model for Hong Kong

State-of-the-Art Technology

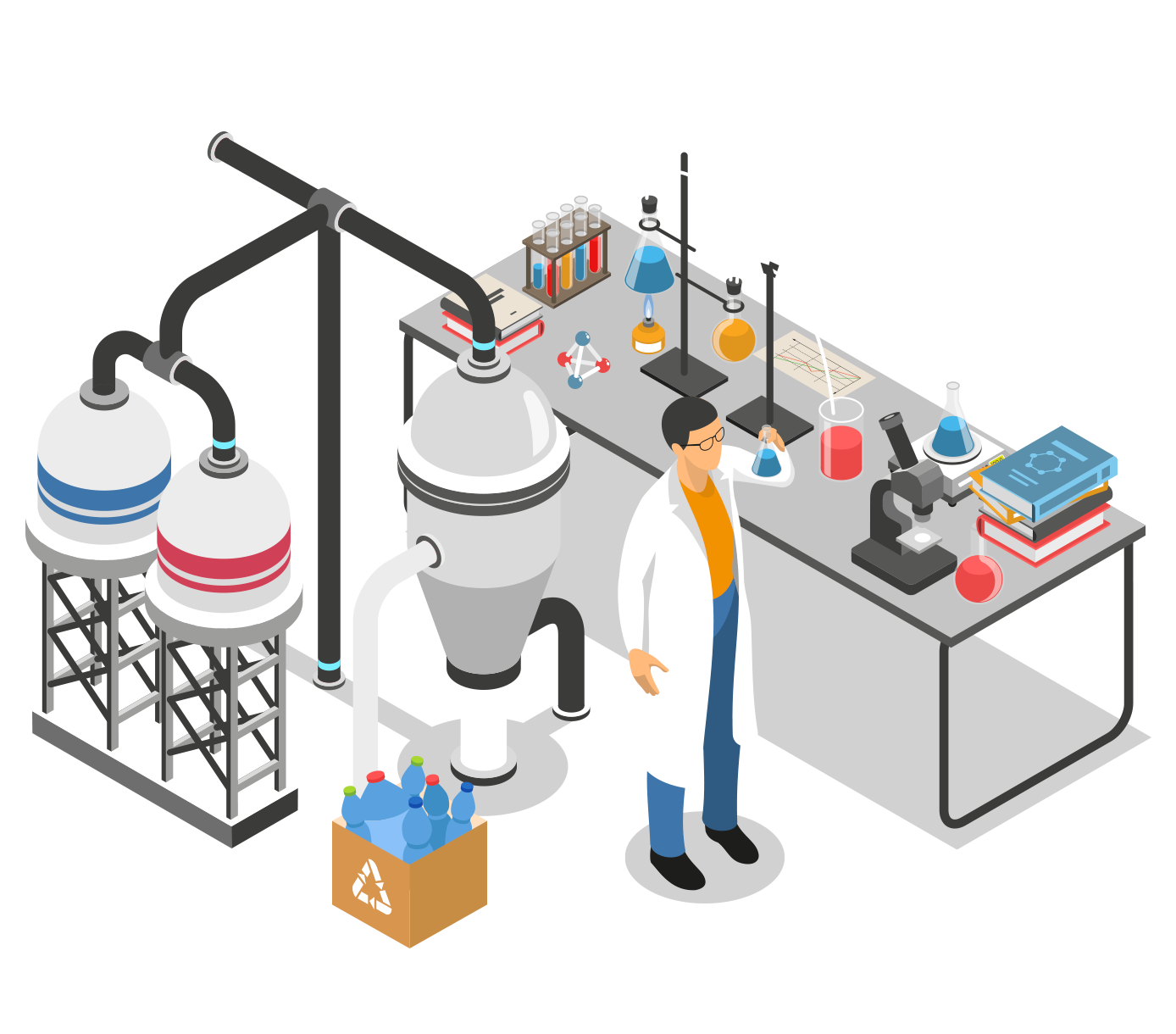

We jointly developed our pyrolysis technology with our Japan and China partners that optimizes efficiencies and oil yield, while mitigating environmental concerns

Show-Case

To set up a pyrolysis processing operation that covers logistics, waste processing, and distribution as a viable solution for Hong Kong on waste plastics

Comprehensive range of oil product offerings

Our pyrolysis solutions offer a full range of crude waste plastics pyrolytic oils (“WPPO”)

Recycling Hub

With support from Government and various stakeholders, make Hong Kong become a clean waste plastics recycling hub

End Game

To create a sustainable solution to waste plastics, delivering circular economy and reducing carbon footprint

100%

Reused

Waste plastics are converted into crude oil and char that can be reused as energy sources

90%

Waste plastics to WPPO Conversion

Waste plastics to WPPO conversion can reach as high as 90%

100%

Clean

We make use of our proprietary pyrolysis technology to process waste plastics. The process is 100% clean with minimal pollution

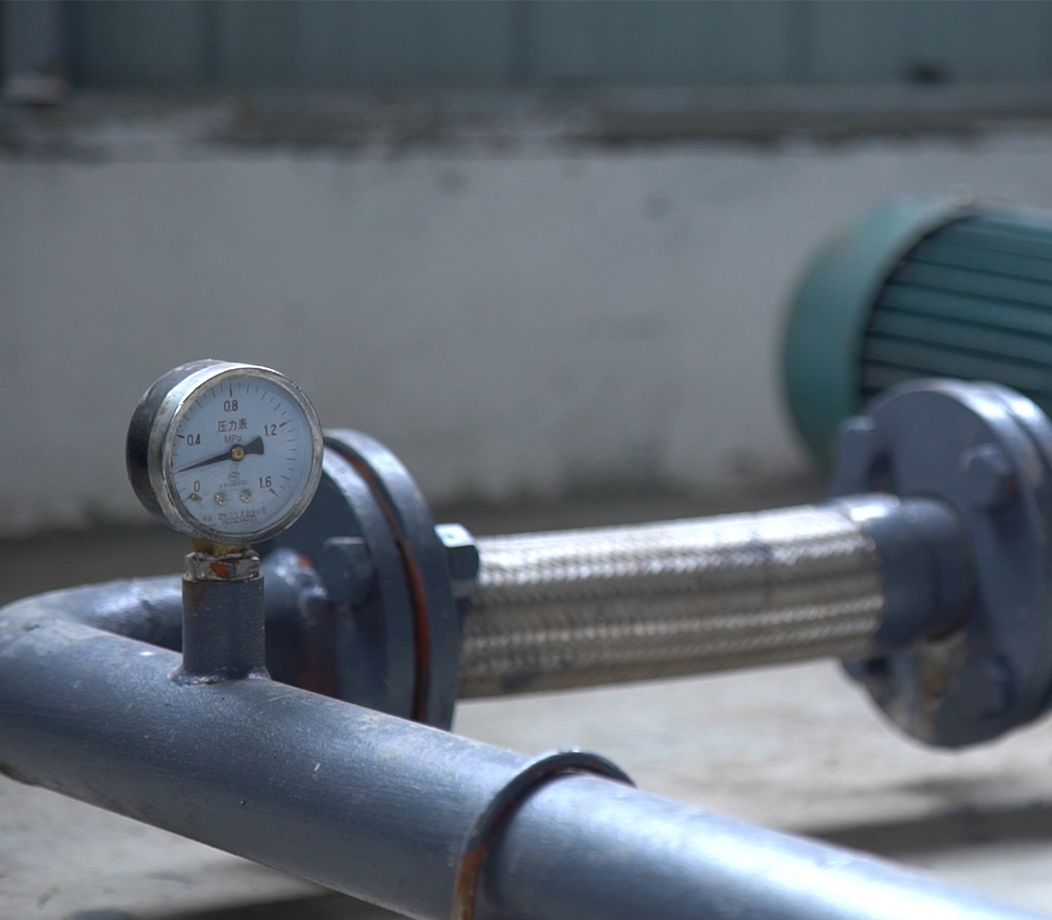

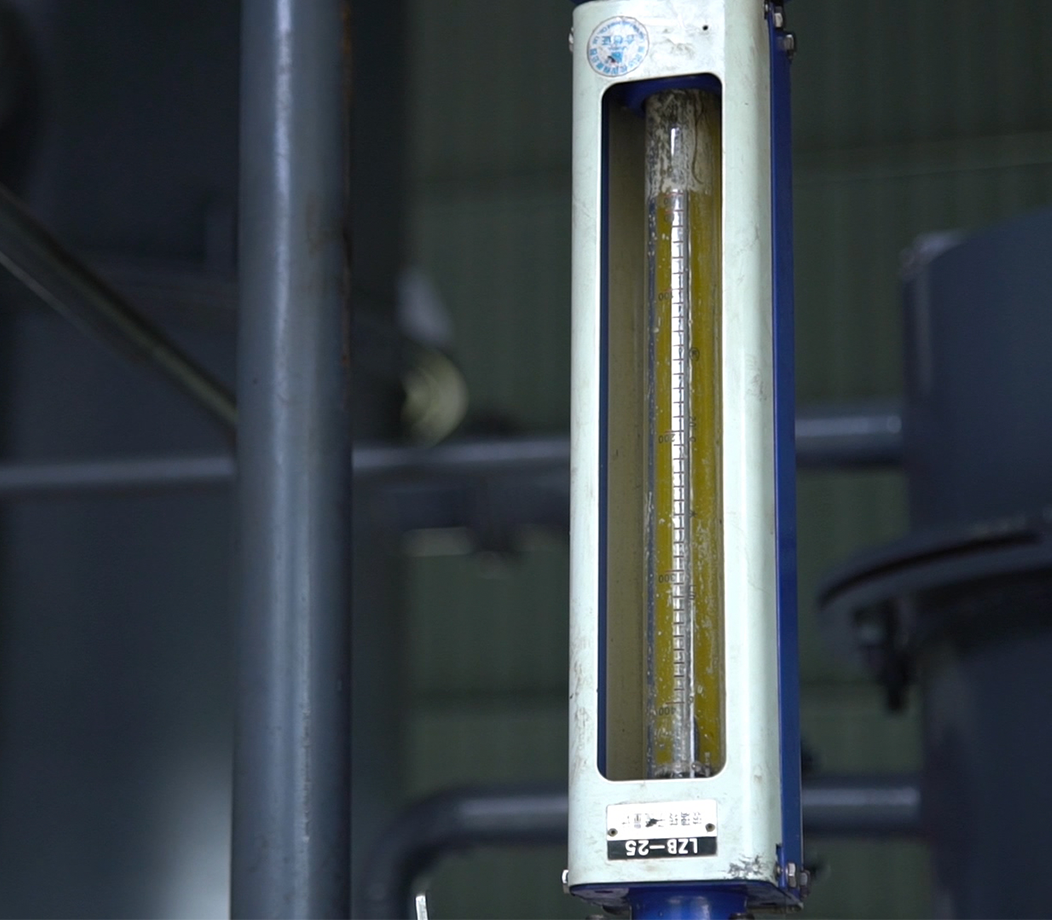

Key Characteristics of our pyrolysis apparatus

R&D Driven

With the core pyrolysis system in place, we are currently focusing our effort on R&D. We set up a R&D center at the Hong Kong Science Park with aim to do the following:

Latest News

Coronavirus face masks that end up in the sea will take 450 years to degrade, marine conservation group warns

Discarded surgical face masks will add to the mountain of

廢塑膠裂解及催化劑研究進展與展望

一、廢塑膠裂解催化劑研究進展 1、裂解的獨特性:通過裂解法將廢塑膠轉化為燃料油的技術既可以解決環境污染問題,又能夠緩解能源緊缺問題,尤其可以從根本上解決難以回收的低密度聚乙烯 (LDPE)、聚丙烯 (PP)和 聚苯乙烯 (PS)等類型的塑膠以及混合廢塑膠的回收利用問題,是目前廢塑膠回收利用技術中非常具有前景的研究方向1。 2、熱裂解:反應溫度高,反應時間長,所得汽油辛烷值低,且含有大量烯烴,誘導期短;柴油凝點高,十六烷值低,含蠟量高;輕油收率低,產品品質較差。 廢塑膠熱裂解製油技術是當前較成熟的廢塑膠回收利用技術2。 3、催化裂解:催化裂解是在催化劑存在條件下進行的裂解過程,在實際反應過程中熱裂解和催 化裂解同時發生。

Plastics – Friend or Foe?

Take a look around you, we are surrounded by plastics.